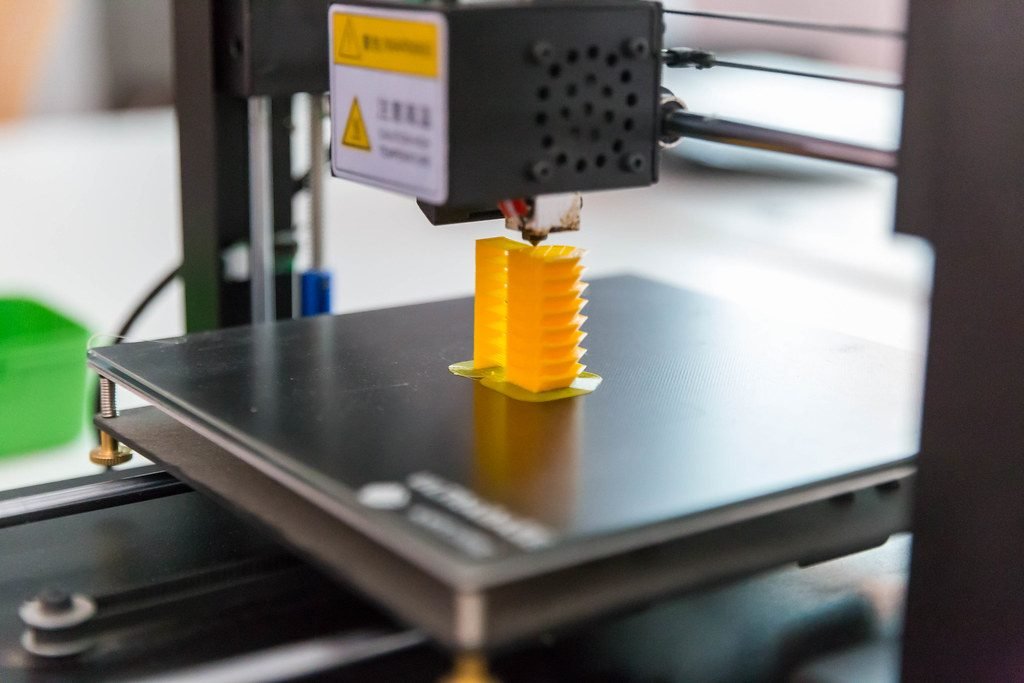

Also known as additive manufacturing, 3D printing is quickly on the rise. This technology is promising to be a significant game-changer in many organizations and companies. Large manufacturing companies are now printing airplane parts while others have begun experimenting with prosthetics in an attempt to churn out artificial body parts. This industry has been growing at a very fast rate in the past few years. With a growth rate of about 12.5% in recent years, the industry is expected to hit USD $ 3 billion by the year 2020. You can get some amazing 3D printers at io3dprint.com. Here are some of the reasons for this growth.

Rapid Growth in Usage

Companies in different industries are using technology for more than just prototyping. 3D printers have become more accurate, are printing objects faster and in larger sizes. They have not only enhanced the quality, but also the volume which was a barrier to this technology owing to the high costs of production. Now, there is no need for printing small objects then assembling them to the desired size. Lowering the cost of production due to increased volumes means that the companies in this industry can now cover their costs and still print out low cost and functional items suitable for mainstream markets.

Printable Materials

3D printers are producing not only plastic items as they used to, but also items made of other materials like metals. About five years ago, printable materials in 3D were very limited. Now, they have more than doubled. The good thing is that it is also possible now to have a mix of these materials. A 2017 survey showed that printing in plastic declined from a high of 88 to 65 percent, while printing in metal increased rapidly to 36 percent from 28. The rapid increase in metal printing has contributed to the increased growth of this industry considering the importance and rapid use of metal.

Improved Technology

In line with the speed of printing, the industry has received a boost from improved technology. Initially, most printers were using the Selective Laser Sintering (SLS) to print metal parts. This technology was not only slow and cumbersome, but also expensive. Recently, a new technology called binder Jet metal printing has been introduced. This technology is faster and has the potential to reduce the time taken by the previous technology by half. If then, products printed using this technology will still go through a post processing process using the older technology to get the finished product, but it will still be much faster than before.

Large Players Joining the Industry

As the 3D industry continues to grow, large multinational companies have also gained interest. These companies are bringing in new technology and encouraging further research thus propelling the industry even more. They have also strengthened the 3D industry’s credibility and drawing more consumers thus, growing the market. The more consumers get confidence with 3D items, the more the market grows, consequently growing the companies’ revenue and propelling the industry’s growth.

World inside pictures Collect and share the best ideas that make our life easier

World inside pictures Collect and share the best ideas that make our life easier